Product Overview

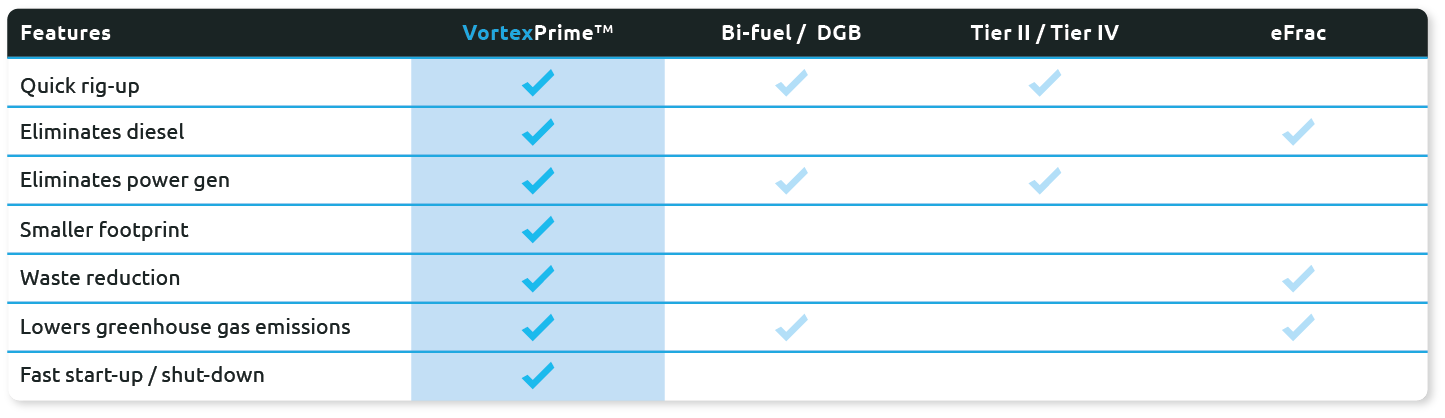

Catalyst’s newest, innovative product – VortexPrime – is the first-of-its-kind fleet in the fracing marketplace using direct-drive turbine technology. In the past, fracing fleets had to choose between cost savings and ESG. With VortexPrime, it’s now possible to have both fuel savings and lower emissions. Using VortexPrime will result in cleaner, safer, environmentally friendlier, and more cost-efficient production.

VortexPrime™

Fully Self Contained

Each compact VortexPrime unit features patented technology that delivers power and performance.

- 5,000 HHP per unit

- 20+ BPM per unit

- 48′ bumper-to-bumper

Consistent Pump Hours

Predictable performance matters.

- 24/7 continuous pumping

- Best-in-class pump efficiency

Boosted Savings

VortexPrime uses 100% clean-burning, natural gas and can deliver up to:

- $1.5 million in fuel cost savings per month

- 40% lower greenhouse gas emissions

- 95% waste reduction

Smaller Footprint, Faster Rig-up

Rig-up in 12 hours.

- Only requires 8 to 12 pumps versus 24 to 30 (standard fleet)

- 55% smaller footprint

- Optimal for small locations

- Ideal for simulfrac

24/7 Support

We’re more than a service company, we’re your partners.

- Locally trained and certified crew

- Permian Basin headquarters

- In-house manufacturing

Safety

Our ongoing training keeps your project safe.

- Automated controls protect operations

- Less equipment, less exposure, less maintenance actions, and improved component reliability reduce risks

Performance Since Inception

*Savings achieved by using CNG.

VortexPrime™ at Work: Catalyst Shares Results of Recent Case Study

Catalyst Energy Services COO, Seth Moore, joins Oil & Gas Journal Editor in Chief, Chris

Ways to Increase ESG Through New Flaring and Fracturing Technology

Recorded October 13, 2022 In this panel discussion, our Seth Moore talks about the importance

Greener: Heard at the Pump

Recorded May 17, 2022 At Hart Energy’s DUG Permian Conference, Catalyst COO Seth Moore joins