Petrochemicals are chemical compounds that are extracted by refining and processing petroleum (crude oil) and natural gas. They are important components in many of the products that we use every day such as plastics, soaps, fertilizers, paints and insulation. Furthermore, petrochemicals provide the necessary raw materials to manufacture innovative energy technology such as solar panels, wind turbine blades and electric vehicle parts.

Petrochemicals are classified into three groups: Olefins, Aromatics, and Synthesis Gas. Each of these petrochemicals provides the basis for items that are fundamental to a functioning global society.

| Type of petrochemical | Produces |

| Olefins | Ethylene – manufactures polyester, antifreeze, solvents, film and plastics Propylene – acrylics, rubbing alcohol and carpets Butadiene – synthetic rubber, carpet fibers, paper coatings and plastic pipes |

| Aromatics | Benzene – plastics, paints, glues and adhesives Toluene – solvents, gasoline additives and explosives Xylene – plastics, synthetic fibers, assists in refining gasoline Naphthalene – insecticides |

| Synthesis Gas | Ammonia – fertilizer Methanol – formaldehyde, silicone rubber, plastics and polyester |

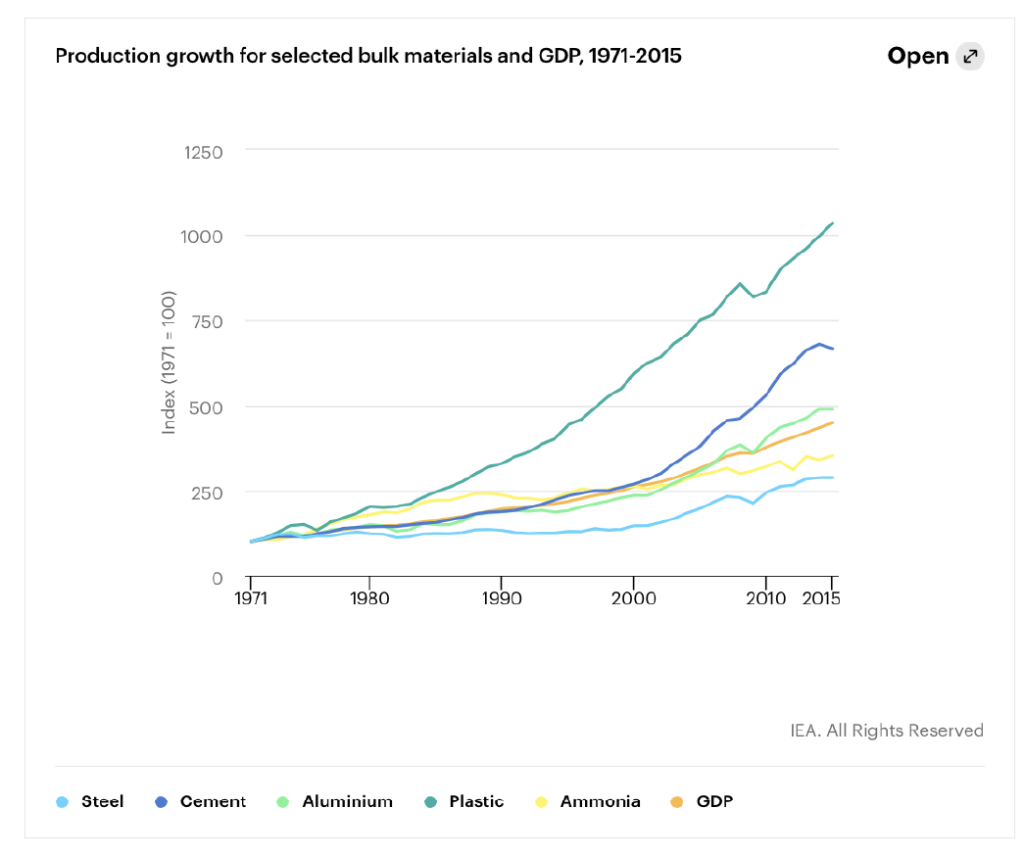

According to the International Energy Agency (IEA), the interest in petrochemicals has been surging, “Demand for plastics—the most familiar group of petrochemical products—has outpaced that of all other bulk materials (such as steel, aluminum or cement), and has nearly doubled since 2000.”

Petrochemical feedstock currently accounts for 12% of the global oil demand. The IEA expects this demand to increase as developing economies continue to grow. “The growth in demand for petrochemical products means that petrochemicals are set to account for over a third of the growth in oil demand to 2030, and nearly half to 2050, ahead of trucks, aviation and shipping.”

As demand increases, it becomes more imperative for the energy industry to prioritize incremental improvements in the development of green technology. With a focus on this change, there is an opportunity for the industry to be a pivotal leader in the evolution of environmental, social and governance (ESG) policies.

Technological innovation inspired Catalyst Energy Services to develop Vortex PrimeTM–the first-of-its-kind fleet in the hydraulic fracturing sector using natural-gas powered, direct-drive turbine technology. VortexPrime decreases CO2 equivalent greenhouse gas emissions up to 40% compared to Tier 4 diesel technology and reduces up to 99% of waste materials. To learn more about this game-changing technology, check out https://catalystenergyservices.com/products/.

About Catalyst Energy Services

Catalyst Energy Services started with the idea that technology is the key to the future. We take the stewardship of preserving our world’s resources seriously and are dedicated to constantly innovating our sector of the energy industry to achieve cleaner, safer, and optimized production. Built by an accomplished executive team with over 100 years of hands-on experience in the field, engineering, and business management, we are an emerging stimulation service company specializing in hydraulic fracturing treatment.